CJX2 AC Contactor Motor control and protection

Introduction

The CJX2 AC Contractor is a versatile and reliable component ideal for use in circuits with an AC frequency of 50Hz or 60Hz. With a rated insulation voltage of 660V and operating voltage up to 800V, it is suitable for a wide range of applications. Specifically, in AC-3 type circuits, it can handle rated operating voltages of 380/400V and rated operating currents up to 95A, making it ideal for tasks such as making, breaking, frequent starting and controlling AC motors.

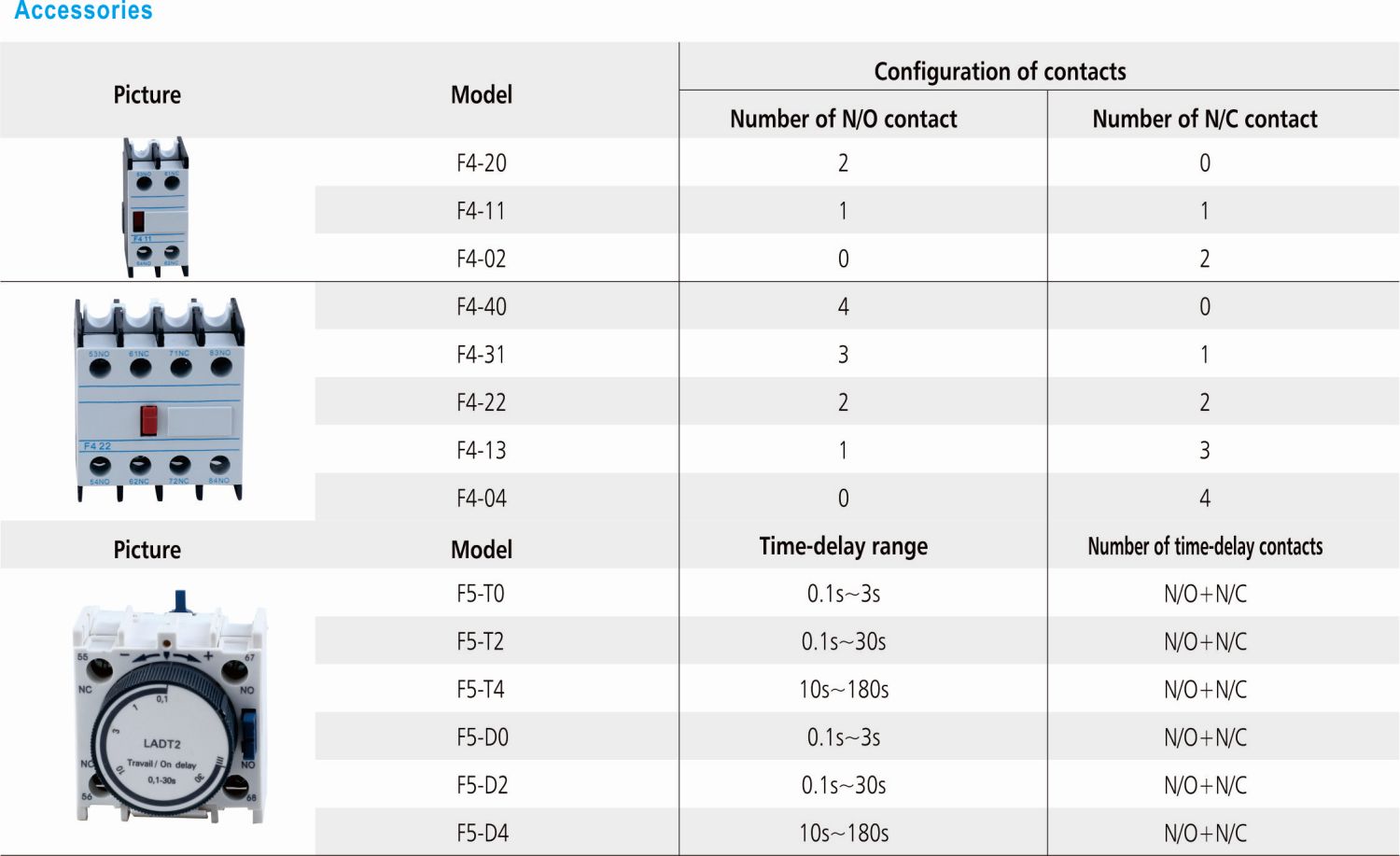

In addition, after the CJX2 AC contactor is combined with the auxiliary contact block, timer delayer, and mechanical interlocking device, it can be transformed into a time delay contactor, a mechanical interlocking contactor, or a star-delta starter. In addition, it can be combined with a thermal relay to form an electromagnetic starter, further expanding its functions and application scope. It should be noted that this contractor is manufactured in accordance with IEC60947-4 standards, ensuring its quality and reliability.

The 3-pole normally open contact type of the CJX2 AC contactor makes it ideal for connecting and breaking circuits over long distances, as well as for frequent starting and control of AC motors. Its contacts can also be assembled into modular auxiliary contact groups, air retarder, mechanical interlocking mechanism and other accessories, providing flexibility and customized options for various industrial needs. In addition, it is compatible with quality standards such as IEC 60947.4, NFC 63110, VDE0660 and GB14048.4, further proving its reliability and performance.

Featuring low power consumption, lightweight design and long service life, the CJX2 AC Contractor is designed to provide superior performance in industrial environments. It complies with IEC60947-4-1 standards to ensure safe and reliable operation, making it a trustworthy choice for a variety of industrial applications. Ensuring that the rated voltage of the coil is 380V AC is very important to ensure the smooth operation of the equipment.

The CJX2 series offers a range of electromagnetic contactors designed to meet different industrial needs. For example, the CJX2-0910 model uses a 220V 50/60Hz coil, has a 3-pole and normally open configuration, and is capable of handling 9A at 380V. In addition, the CJX2-0910Z model offers flexible coil voltage options including DC12V, DC24V, DC48V, DC110V and DC220V, making it suitable for a variety of industrial electrical applications. These contactors are designed to provide safe and reliable performance, ensuring operational efficiency and peace of mind.

The CJX2-1210 model is designed for higher voltage applications, with a rated insulation voltage (Ui) of 690V and a rated current of 12A. This AC contactor has 3 poles, including 1 normally open (NO) contact, and a coil voltage of 380V/400V (50Hz), making it ideal for demanding industrial environments, providing strong and reliable performance.

Tthe CJX2-1211 AC contactor provides 12A rated current and has 3 poles including 1 normally closed (NC) and 1 normally open (NO) contact. With a coil voltage of 50/60Hz and optional Din rail mounting, the contactor provides a versatile and environmentally friendly solution for industrial applications, ensuring reliable operation and easy installation.

The CJX2-1201 and CJX2-1810 models have coil voltages of 24V 50/60Hz and are available in 3-pole, normally closed (NC) and normally open (NO) configurations respectively. Capable of handling 12A and 18A respectively at 380V, these contactors provide reliable, efficient performance for a variety of industrial applications.

The CJX2-3210Z contactor is designed for high current applications, with a rated insulation voltage (Ui) of 690V and a rated current of 32A. This contactor has 3 poles, including 1 normally open (NO) contact, and a coil voltage of DC 24V, providing a powerful and versatile solution for industrial AC applications, ensuring safe and reliable operation.

The CJX2 series electromagnetic contactors provide a comprehensive selection to meet the diverse needs of industrial applications, providing safe, reliable, and efficient performance under various voltage and current requirements.

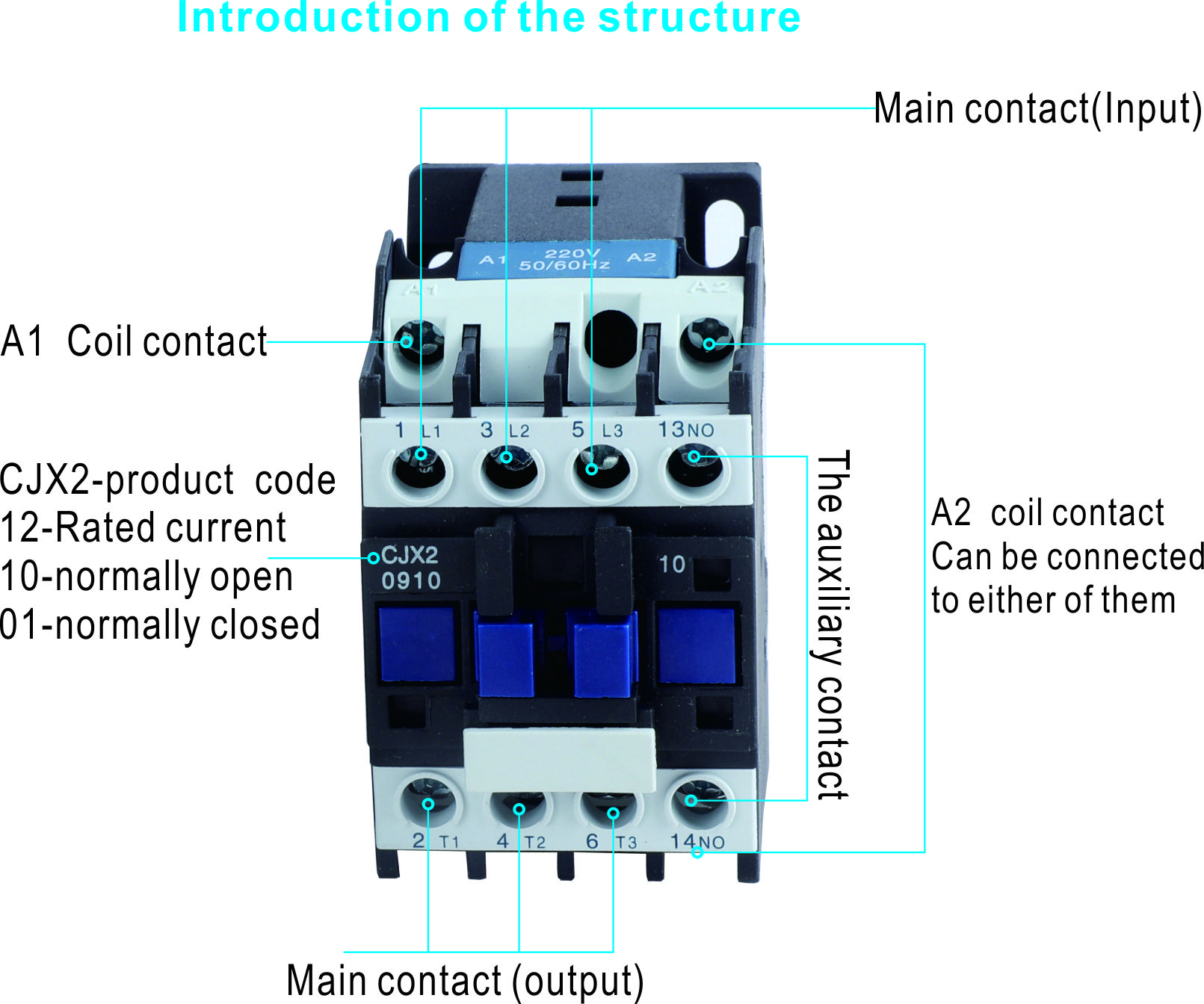

Product Description

Number of contacts

The "10" designation indicates a configuration with 3 normally open (N/O) main contacts and 1 normally open (N/O) auxiliary contact, available in various current ratings including 9A, 12A, 18A, 25A, and 32A. This configuration is ideal for applications requiring the flexibility of multiple normally open contacts and auxiliary contacts.

The "01" designation indicates a configuration with 3 normally open (N/O) main contacts and 1 normally closed (N/C) auxiliary contact, available within the same rated current range. This configuration provides the versatility of a normally closed auxiliary contact to meet a wide range of industrial control requirements.

The"11" designation indicates a configuration with 3 normally open (N/O) main contacts, 1 normally open (N/O) auxiliary contact, and 1 normally closed (N/C) auxiliary contact, available Higher current ratings include 40A, 50A, 65A, 80A, and 95A. This configuration provides the flexibility of normally open and normally closed auxiliary contacts for applications with more complex control requirements.

The"04" designation indicates a configuration with 4 normally open (N/O) main contacts, offering a range of current ratings including 9A, 12A, 25A, 40A, 50A, 65A, 80A and 95A. This configuration is suitable for applications requiring multiple normally open contacts without auxiliary contacts.

The"08" designation represents a configuration with 2 normally open (N/O) main contacts and 2 normally closed (N/C) main contacts, available within the same rated current range. This configuration provides a balance of normally open and normally closed contacts, providing versatility for a variety of control and switching applications.

The clear, systematic numbering system of the CJX2 Series contacts provides users with a straightforward way to identify the specific configuration and capacity of the contactor, ensuring the correct solution is selected for a wide range of industrial control and switching needs.

The most important features:

1. The iron core is made of solid materials to enhance the smoothness and sealing of suction and provide safe and efficient operation. This design ensures stable and consistent performance even under demanding conditions.

2. The use of highly conductive silver alloy contacts is a key feature as it ensures a reliable electrical connection and minimizes the risk of voltage drops. Additionally, the flame-retardant casing provides an extra layer of safety, making this product suitable for use in a variety of industrial and commercial environments.

3. The use of copper coils with strong electromagnetic attraction when energized is another key feature. This design ensures robust and reliable operation, allowing for efficient switching and control of circuits.

4. The product adopts an all-plastic buckle structure, making full use of the elasticity of the plastic material itself. This innovative design eliminates the need for screws and special tools during installation or removal, saving time and labor while also reducing material costs. Snap-on construction provides a safe, hassle-free installation process, helping to improve overall efficiency and ease of use.

Together, these key features increase the product's robustness, reliability and ease of installation, making it a versatile and practical solution for a variety of electrical applications.

Normal Working and Installation Conditions

1. Ambient temperature: The designed working environment temperature range of the AC contactor is -5℃ to +40℃, and the average value within 24 hours does not exceed +35℃. This temperature range ensures optimal performance and service life of the device under normal operating conditions.

2. Altitude: The AC contactor is suitable for use below an altitude of 2000m, ensuring its compatibility with a wide range of installation locations.

3. Atmospheric conditions: In an environment where the temperature reaches 40°C, the relative humidity of the atmosphere should be kept below 50%. At lower temperatures, higher relative humidity may exist. In addition, the maximum monthly relative humidity should not exceed 90%. If condensation forms due to temperature changes, special precautions should be taken to ensure the continued reliability of the equipment.

4. Pollution level: The AC contactor is designed to operate in a pollution level 3 environment, ensuring its recovery capability in moderately polluted environments.

5. Installation Category: The installation category of the AC contactor is designated as Category III, indicating that it is suitable for use in fixed installations.

6. Installation conditions: The inclination between the installation surface and the vertical surface should not exceed ±5° to ensure correct alignment and installation of the equipment for optimal performance and safety.

7. Impact and impact: It is recommended that the AC contactor be installed and used in a place without strong vibration and impact to ensure the stability and reliability of the equipment during operation.

These specified operating and installation conditions are essential to ensure reliable, safe operation of the AC contactor in a variety of environments and operating settings. Complying with these conditions will help maintain the performance and service life of the equipment and contribute to the overall safety and efficiency of the electrical system.

010203040506

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC80-2P

JC80-2P JC80-4P

JC80-4P JC125-2P

JC125-2P JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JCR2-63

JCR2-63 JCR1-40

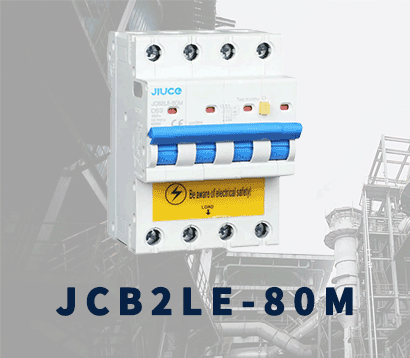

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

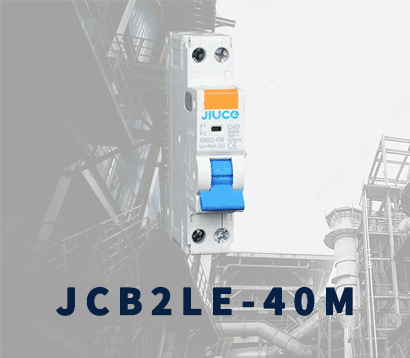

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

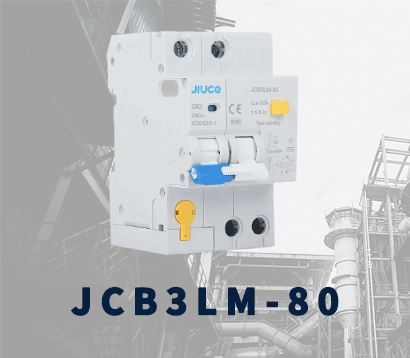

JCB1LE-125 JCB3LM-80

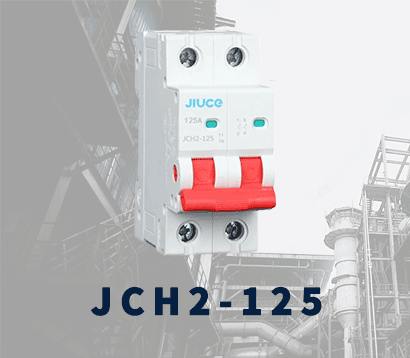

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JC3AF-S

JC3AF-S JC3AE

JC3AE JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC P-250A-3P-A

P-250A-3P-A WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500